Metal Detector Certified Test Pieces Can Make A Real Difference

April 5, 2018

Using Metal Detection Test Pieces in the Food Industry Helps Put Safety First

June 26, 2018

Metal Detection Test Standards

Why Use a Metal Detector and Its Test Pieces In The Food Industry?

The use of a metal detector and test pieces in the food industry has become standard, and with good reason. It is crucial that all food product manufacturers carefully inspect their products to ensure that no contaminants are present. First, this guarantees the safety of their product and the consumer. Second, it saves money by avoiding a production shut down or paying legal expenses should any contaminated products reach consumers.

Of course, when considering the use of a metal detector in food processing, people might wonder, “Why is this necessary?” After all, if a manufacturer is adhering to all health and safety standards, why use a metal detector? That couldn’t be further from the truth. Even the cleanest, most well-run facility can have the unfortunate issue of metal contamination. So really, there is no reason not to incorporate the use of a metal detector.

Contamination

So where is this contamination coming from? How do metal detector test pieces help find it? There can actually be many different sources of possible contamination within a food manufacturing plant. Unclean working conditions are just one of those possibilities. In fact, the majority of contamination is not caused by unsanitary conditions or lax work habits. The greatest culprit is the natural degrading of the manufacturing machinery.

All around a food production plant, there is machinery and a great deal of that machinery is made of metal. Over time, that metal can rust, wear down, or break apart. And the resulting metal particles can find their way into food as it passes through the machinery. The purpose of metal detectors is to find those particles and prevent affected products from reaching the public.

The Process

The process involved in a metal detector food inspection is really quite simple. Most food production takes place using some kind of conveyor system, gravity feed or inline processing, passing the product through various stages of preparation until it is packaged and sealed. A metal detector should be incorporated, ideally at the very end of this process, to carefully scan each product for the presence of any metal particles. If a particle is detected, then the product in question would be automatically rejected before it can be approved for shipping.

There are several types of metal detectors that food industry technicians can use. The most common, with the goal of detecting ferrous, non-ferrous and stainless steel metals, relies on the principal of “balanced coils” while the other uses a magnetic field system to detect metal typically within products that are wrapped in foil.

The Difference

The difference between the two has to do with the way contaminants are detected. In a balanced coil system, food is “scanned” while the transmitting coil generates a magnetic field. The presence of a metal in the product creates a change in the magnetic field between the receiving coils. In a magnetic field system, the contaminants are magnetized as they pass through. The magnetized particles then trigger a detection system within the coils that highlights the contaminant.

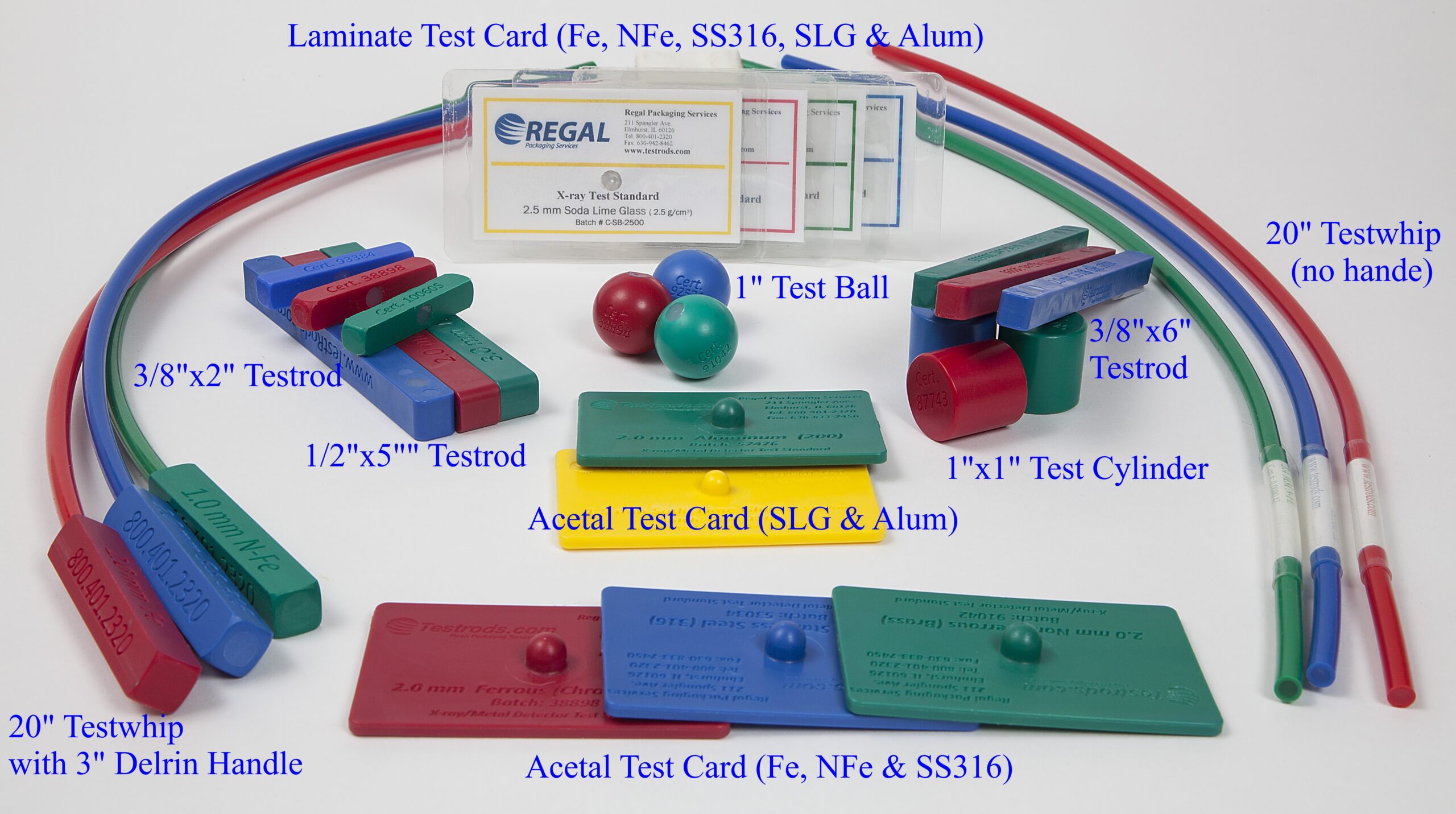

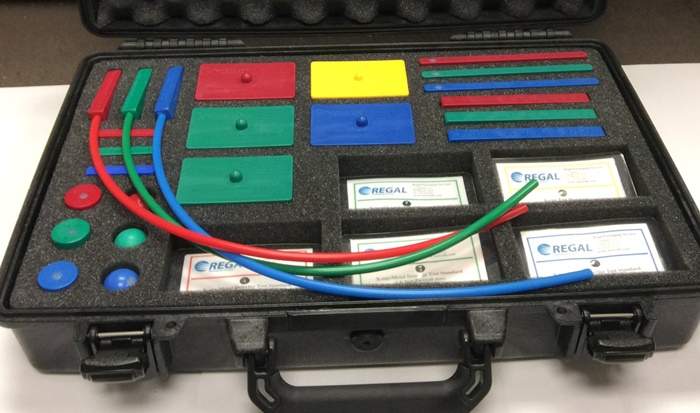

No matter which system is used, it is absolutely crucial that it be tested regularly. This is the only way to make sure, in an ongoing way, that it is functioning properly. To do this, test pieces are used in the metal detector food inspection process. These pieces are made from a variety of plastics and contain “seeds” of metal. We sell them variety of sizes and shapes based on the particular demands of your application and the product being tested.

Test Pieces

The test pieces are placed within a collection of finished products, usually toward the end of the pack. For best results, the pack of finished products should be passed through the equipment 3x. Place the test piece at the leading, middle and end edges of the pack. If your machinery is working properly, it should detect the metal in the test pieces and reject them.

Regal Packaging Services has been providing metal detection test pieces for food industry companies since 1998. We carefully manufacture and certify each test piece so that our customers are guaranteed to get a quality product. And one that meets the standards of the food industry. And we can customize your pieces to fit your exact specifications. You’ll know you’re getting the perfect fit every time. So don’t take chances with your metal detector maintenance…come to Regal and get the best.

1 Comment

It was interesting to learn about how food products should be tested at the end of the production process so that affected products don’t reach the public. I can understand how it could be very important for a business to make sure that their food is safe to consume so that they don’t get sued or charged for anything. It could be really helpful for them to make sure that they can check for metal efficiently so that they know there isn’t any in their product.