How Do You Test a Pipeline System?

April 1, 2025

Multiscan Metal Detection

June 1, 2025 Don’t Miss What We Offer for Food Safety

Don’t Miss What We Offer for Food Safety

The food industry is an essential and vast sector that encompasses the production, processing, packaging, distribution, and marketing of food products to meet the ever-increasing demand of consumers worldwide and we consider Regal’s role in the food industry nearly as important as any other component. It plays a crucial role in nourishing the population and driving economic growth across the globe.

Most people think of the food industry as the companies that grow, manufacture, process, package or distribute food, whether it’s animal, plant, “man-made,” organic or genetically modified. We think about the various branches of the food industry: agriculture, food service, food manufacturing and retail.

The food industry creates jobs at various stages of the food supply chain which contributes to the overall GDP through the production and sale of food products. And it supports other industries such as packaging, transportation, and logistics. The industry also drives innovation and creating new business opportunities all along the way.

It is often the “new frontier” of food that captures the attention and prints the headlines, like the rise of plant-based and alternative proteins to cater to the growing demand for vegetarian and vegan options.

Then there is increasing focus on sustainability, with companies embracing eco-friendly policies and waste reduction. Furthermore, we have the innovation of technology with an ever increasing plethora of food delivery apps, smart appliances, and blockchain for supply chain supervision. And let’s not forget an emphasis on health and wellness, with consumers in search of purposeful, wholesome foods and beverages.

But to the average consumer, there is a hidden industry behind these companies, namely, food technology. These are the companies that provide food processing, transport, packaging and handling equipment. Someone has to design and manufacture the machine that will package breakfast cereal both in the bag and the box the bag goes in. And that’s just the tip of the proverbial iceberg.

These manufacturers have to deal with a plethora of safety concerns, not only for the people working in the plant, but also for everyone working on the farms, orchards and ranches. And then there’s the safety of the food itself.

That’s where Regal Packaging Services meets the need. We represent Fortress Technology, selling and servicing metal detectors and checkweighers. Additionally, we rent metal detectors for those times when you need a temporary replacement unit or you need to run a quality control check on food that’s on hold. We also audit all brands of metal detectors, so when you’re getting ready for an audit, you can be sure each detector has been 3rd party inspected and meets the standards of your HACCP plan.

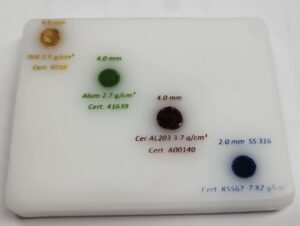

And, here in the Testrods division of the company we manufacture our own line of metal detection and x-ray inspection verification test pieces. We are ISO certified and consider our role in the food safety chain a very important component of what shows up on breakfast tables all over the world. Currently, we have customers in 27 different countries, not including the US. Our test pieces are used from Ecuador to Australia, from South Africa to Poland.

We have 17 different contaminant types in a wide variety of sizes, including:

|

Aluminum |

Delrin (Acetal) | Polypropylene |

|

Bone Simulate |

EPDM Rubber |

PTFE (Teflon) |

|

Buna Rubber |

Ferrous (Chrome Steel) |

PVC |

|

EPDM Rubber |

Fused (Synthetic) Quartz | Soda-Lime Glass |

|

Viton Rubber |

Non-Ferrous (Brass) |

Stainless Steel 316 |

| Ceramic AL203 | Nylon |

Viton Rubber |

| Ceramic ZrO2 |

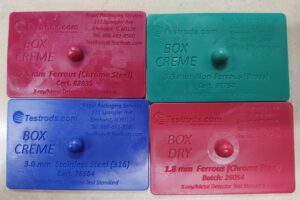

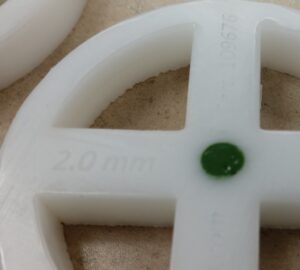

Our standard test pieces are:

| 1/2″ x 5″ Rods (Wands) | 1″ Cylinders |

| 3/8″ x 2″ Rods (Wands) | 3/4″ x 1/4″ Pucks |

| 3/8″ x 6″ Rods (Wands) | 1″ Cubes |

| 20″ (flexible) Whips | 1.5″ Cubes |

| 1″ Balls | Laminate Cards |

| 1.5″ Balls | Acetal Cards |

| 2.0″ Balls | Thermoform Cards |

| Nylon Case | Hard Shell Cases |

Beside those standard test pieces, we have the capability to manufacture a wide range of custom test pieces. If you can imagine it, we can probably make it. Whether it’s a replica of an ice cream cone, a candy bar or a 24ft flexible “rope” for a closed loop overhead application, let us know and we’ll come up with the perfect design. And every test piece comes with a non-expiring certificate of conformity. Call us at 866-691-8560, email testrods@testrods.com or find us on LinkedIn. Or, if you’re looking for a metal detector and your plant is in Ilinois, Indiana, Iowa or Wisconsin, call 630-942-8461.