The 8 Pillars – #3, Engagement of People

November 1, 2025

The 8 Pillars – #5, Improvement

January 1, 2026 The 8 Pillars – #4, Process Approach

The 8 Pillars – #4, Process Approach

As an organization we understand that a desired result is achieved more efficiently when activities and related resources are managed as a process or series of interconnected processes.

As ISO.org explains it, “The process approach includes establishing the organization’s processes to operate as an integrated and complete system.

-

-

-

-

- The management system integrates processes and measures to meet objectives

- Processes define interrelated activities and checks, to deliver intended outputs

- Detailed planning and controls can be defined and documented as needed, depending on the organization’s context.”

-

-

-

What it means for us is that we approach everything we do systematically. To keep everything organized from the point of sale through production and eventual delivery of product, each step has a predetermined set of steps to ensure quality of product and an effective, mutually beneficial relationship with our customers. In essence, we’re able to measure how the product gets from point A to point B by knowing which step in the process it’s in.

Production, of course, will take place, for most orders, before we ever “greet the customer,” whether that’s through our website, an email, a phone call or a message from our in-the-field sales or tech staff who are working face-to-face with our constituency. But it always happens with the customer in mind. Manufacturing takes place as if the customer were watching over our shoulder and waiting for the product that will help deliver their goods will make it to the marketplace as food safe commodities.

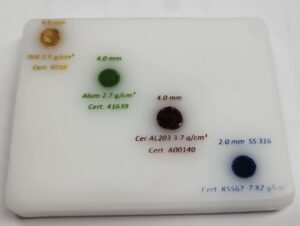

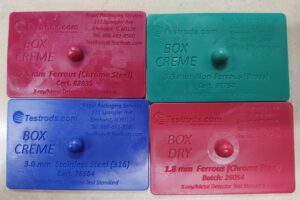

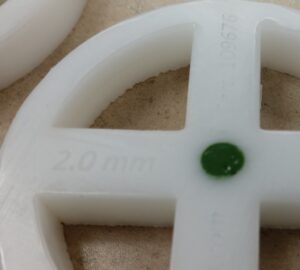

The standards set meet not only the certification requirements for the food, pharmaceutical and textile industries but also take into consideration the various limitations and needs for size and type test piece needed. Beyond that, attention is given even to the aesthetic appeal of our test pieces. How easy is it to read the type or engraving? Will it be noticeable if it gets left behind somewhere? Will it last on the production floor over years of daily use?

We also need to take a process approach with our vendors. Can they supply material with the necessary certifications and proof of certifications? Is the product supplied consistent, and does it meet tolerance requirements? How quickly can it be obtained and in what quantities?

On the marketing side, the same kinds of questions are asked. How easy is to use our website? What kind of response can a customer expect if they email a PO? Call to place an order? Get a question answered before or after ordering? We know what questions to ask when an order is placed to confirm we have all the details needed. When an order is placed online with what we suspect may be a mistake, we follow-up with our customers to be certain they get what they actually need, and they won’t have to go through a return process.

For instance, in a recent order, the customer ordered our 6 inch testrods: 1.5mm Ferrous, 2.0mm Non-Ferrous and 2.5mm Non-Ferrous. We recognized that the 2.5mm item was probably meant to be Stainless Steel 316, and after contacting the customer, that turned out to be true. And even when a return is needed, our process approach makes that experience simple and painless.

We keep track of how many errors we make in production, sales and shipping. It’s important for us to follow a given set of procedures in order to minimize the mistakes. And when we find the problems are occurring often enough or in a similar pattern, we alter our procedures. Fortunately, we have our processes honed down to the point where making a change is rare. We’re confident we can meet every expectation and standard for our customers and the demands of the industry. Call us at 866-691-8560 or email testrods@testrods.com.

See also Testrods on LinkedIn