Can You Afford to Miss What We Offer for Food Safety?

May 1, 2025

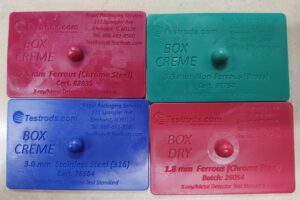

You Need to Use Stainless Steel 316

July 1, 2025 Multiscan Metal Detection

Multiscan Metal Detection

On any given day you may be watching the news when you hear someone say, “You may have purchased food that has just been recalled this week.” Unfortunately, that scenario is more common than any of us would like to believe. In the latter part of 2018, one company recalled over 25,000 pounds of frozen poultry and pork sausage links.

Financial loss and regulatory pressure have compelled many manufacturers to turn to detection technologies in order to prevent these concerns. Metal detectors and X-ray detection systems weren’t always common, and not every food plant has the latest technology has to offer. At Regal Packaging Services we understand the concerns about these issues and can help you mitigate the risks.

METAL DETECTORS

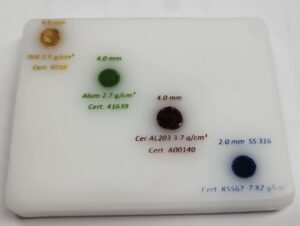

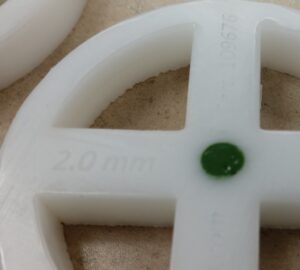

HACCP plans commonly call for the use of metal detectors. You will find them in nearly every food plant. They can be placed at a variety of points on the line, however, they are typically used at or near the end of the line as the last point of protection before a packaged product makes its way to the consumer. Like any technology, it has always had limitations, such as “product effect.” For instance, the detector has to be “calibrated” to the product. This eliminates the effect of a conductive product and susceptibility to “noise” coming from many potential sources in production environment.

Metal detectors make use of coils that are wrapped onto a non-metallic frame and then linked to a radio frequency transmitter and receiver. The transmitter “detects” (by virtue of the interrupted radio signal) any undesired metal and generates the signal and triggering a reject mechanism to capture the contaminated product. Recently, with the introduction of multiscan capability, the metal detection technology has gotten even more intelligent.

THE EVOLUTION OF FREQUENCIES

In the early stages of metal detection technologies, the machine was limited to single, fixed frequency. A detector could find stainless steel contaminant using a high frequency. However, when the product was wet or had high saline content, the detector would be forced to lower the frequency and the resulting sensitivity was lowered. This frequency change required setup by experienced technicians who might require a good deal of time before determining the best frequency for detection of all metal types. This was not an end-user change.

To solve the issue, manufacturers began introducing second and third frequency choices (still utilizing one frequency at a time), giving end-users more flexibility to work with the various products they might be running. A good deal of proficiency was still required to optimize detection.

In the next step of metal detection progress was the expansion of frequency choice via software. The most appropriate frequency for a product could be selected prior to startup by scanning a product several times for “calibration.” This was known as “variable frequency” metal detection. It provided a method for setup without a specialist. The food plant was still forced to live with the “best” frequency compromise and accept its lower overall execution in detection.

In a subsequent technology upgrade enabled detection at two frequencies concurrently, so that performance would be like having a low and high frequency detector in one. This dual-frequency approach improved overall sensitivity, still had its limitations.

THE ADVENT OF MULTISCANNING

Now, multiscan technology is the long-awaited modernization in metal detection. Detectors with this capability can recognize contaminants up to 50 percent smaller (in volume) than previous technologies. With multiscan technology, the machine can scan up to five variable frequencies, raising the probability of discovery exponentially. Fundamentally, it’s like having up to five entirely changeable metal detectors on a production line. The frequencies are scanned thousands of times each second, so that it’s possible to tranmit simultaneously without requiring as much energy.

A hidden advantage of multiscan technology is that it can be used to address electromagnetic interference (EMI), which can come from anywhere in the factory at any time. EMI is characteristically spawned by a motor or variable frequency drive moving through the air into the aperture, obstruction or minimizing the detection signals. Operators can easily look at the monitor of an advanced multiscan detector to determine which frequencies are affected by EMI and adjust correspondingly.

FINDING THE BEST METAL DETECTION SOLUTION

Of course, this is not a “one and done” approach to metal detection. The best way to protect your product and your liability is to have the right people on the line and ensuring that the solution you employ is the right one for your products. It is critical that producer consider their distinctive systems, processes, procedures, equipment, product types and HACCP plans before making a final decision about which solution is used.

Determining the best metal detection application is certainly easier than it used to be. Advanced tools are more consistent and adaptable, creating greater efficiency to food industry manufacturers while requiring fewer trade-offs. The high bar today is multiscan technology, but advancements are inevitable!

As always, email us at testrods@testrods. com or call 866-691-8560.

Taken in part from: Metal Detection: Multiscanning Turns Up Frequency for Food Industry, April 26, 2019, By Bob Ries