Multiscan Metal Detection

June 1, 2025

What is ISO Certification?

August 1, 2025 Why Stainless Steel 316 is a Vital Ingredient

Why Stainless Steel 316 is a Vital Ingredient

Keeping food safe begins with the right processes and procedures. And within those is a HACCP plan that outlines rigorous hygiene, and nickel-containing stainless steel 316 which is the superior, reliable standard in the food industry.

As of October 2024, the World Health Organization reports, “An estimated 600 million – almost 1 in 10 people in the world –fall ill after eating contaminated food and 420 000 die every year.”1

Regulations are increasing the pressure on companies for better outcomes as it relates to food safety. The Food Safety Modernization Act in the US; China’s 2015/6 revisions to the Food Safety Law, tightening of rules on food contact materials in India, and in Europe EDQM’s Technical Guide on Metals and Alloys Used in Food Contact Materials and Articles are just a few examples.

By and large, the aim of new regulations is that material and equipment manufacturers as well as food business operators cooperatively take responsibility for keeping food safe-to-eat from farm to fork.

Food Safety Investments should always be based on sound, science-based regulation can assist in meeting the Sustainable Development Goals (SDG) targets and help reduce food contamination, while guaranteeing acceptable returns to the food industry.

One investment is adhering to the use of nickel-containing stainless steel 316 equipment. Most food related operations, whether it is food processing, catering or domestic cooking, regardless of their size, benefit from the sanitary properties of stainless steel while keeping food safe for shoppers all along the value chain.

This kind of stainless steel does not alter the taste or color of food, does not contaminate the food and it does so while providing outstanding performance as it relates to food safety. It is easily, effectively and efficiently cleansed and decontaminated.

Designed for hygiene

Production materials in the food industry must be able to withstand any build-up of processing procedures as well as be readily disinfected and washed down between production runs. There should be no corrosion and no loss of material into the food in any threatening levels to consumer health. The stainless steel 316 standard (which typically contains 10-14% nickel) maintained in the food industry should be considered as a non-negotiable option. Its machinability into complicated shapes allows fine tolerances to be both achievable and cost-effectively practical.

Cleanability, as you might expect, is key to maintaining hygienic, sanitary conditions. The slick, smooth surface of stainless steel is outstandingly cleanable and will remain so when treated carefully. It withstands wear, brunt force, and variations in temperatures while preventing any build-up of dirt or other “scale.” The naturally self-healing inactive layer prevents corrosion and is more suitable than an applied coating, which may be damaged or degrade over time. The ability to effortlessly wash and sanitize stainless steel allows for the removal of bacteria effectively and simply.

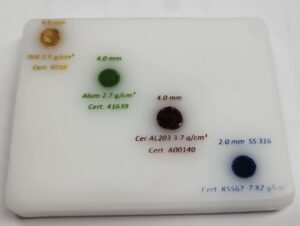

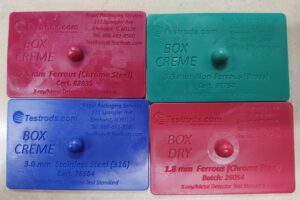

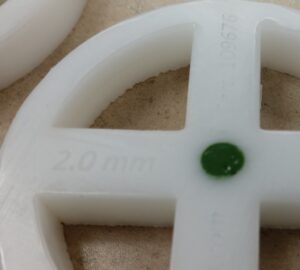

Designed for detectability

There is some contention as it relates to the difference between type 304 and 316L stainless steels although duplex alloys are now being used under more exacting conditions. But 316 provides the better protection against metal contamination. Put simply, this is because 316 is less magnetic and more difficult to detect should it appear somewhere in the food being produced. The theory, then, is that if you can capture and reject this grade metal, you will be able to reject any 304. The reverse would not be true. If you’re testing with a 304 standard, you may miss 316.

So, as you plan for the material in your application, keep in mind that while stainless steel 316 may not be the least expensive on your material needs list, in the long run it will produce the results you want when it comes to safety and liability.

Call us at 866-691-8560, email testrods@testrods.com or use our website and order your stainless steel 316 test pieces today.