The 8 Pillars of the Regal Quality Policy – #1, Customer Focus

September 1, 2025

The 8 Pillars – #3, Engagement of People

November 1, 2025

The 8 Pillars of the Regal Quality Policy – Leadership

If you read our previous article about how we’re customer-focused, then you know we’re discussing the 8 Pillars1 of our Quality Policy. It’s what separates us from our competition and provides you with the best possible product and service you can find anywhere.

Leadership means a lot of different things to different people, and it can have many different definitions. To us, it means our Management Team has committed to creating and maintaining a working environment in which people become fully involved in acquiring leadership skills and our company is a leader in the industry.

Ongoing training is expected of each employee in the Testrods division, including research, reading, webinars, and internal instructional sessions with the sales and tech staff of Regal Packaging Services. It’s our belief that the more knowledge the team has, the better each person will be able to lead, and that includes communicating well as a team and with our constituency. We work diligently to be able to guide the companies we serve and to speak intelligently about what we do and what are the benefits of our product in the interest of food safety.

Within Regal Packaging, there is over 100 years of industry experience in sales, service, auditing, rental and test piece manufacturing. What you get from us is an understanding of the wide array of metal detectors and x-ray inspection systems and operation. So even when your need goes beyond purchasing test pieces, we can help. Our products are being used in 26 countries around the world!

We look at the latest trends in food safety and do our best to prepare whatever is the next product that might be useful. We pioneered the advancement of bone simulate by working with x-ray systems we had onsite and customers who were able to test our product against the kind of bone they might be looking to weed out of their product, whether it was beef, pork, or chicken. It’s no small feat considering that bone is a difficult contaminant to find because it can vary widely based on the size, age, and calcium content (as well as feed used) of the animal.

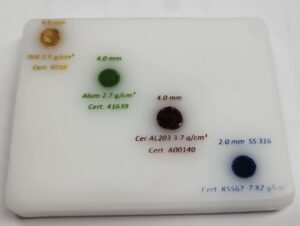

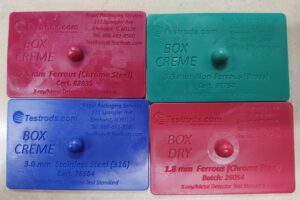

In addition, we’ve been able to assist clients with stone test products, allowing them to safeguard machinery against contaminants that might be coming right off the field or ground. And we have expanded our contaminant selection to 17 different variations, including 2 types of ceramic, soda-lime glass, and quartz. And we guarantee everything we make with the appropriate NIST and FDA certification standards. While some other companies charge for this service, we believe it’s an integral part of what we do in playing our role in food safety.

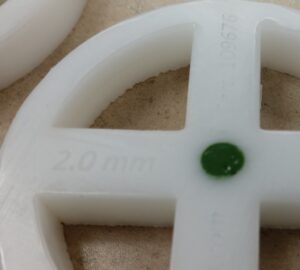

We are continually working on custom orders, and there is a great deal of collaboration on how to design and manufacture what our customers need. For instance, you might not imagine that we would be capable of cutting a test piece that looks exactly like a chocolate bar or a chicken nugget, but after some in-house discussion, there isn’t anything we haven’t yet been able to simulate. Often, an application calls for a test piece to be placed directly on the production stream as if it were an actual product. That’s when our engraving and CNC capabilities put us at the cutting edge (no pun intended) of the test piece manufacturing world. It’s this kind of focus that not only keep our team developing as leaders individually, but also keep the company positioned as an industry leader! We look forward to whatever challenge you present, whether it’s the “ordinary” type and size test piece or the strangest thing you can imagine.