The 8 Pillars – #5, Improvement

January 1, 2026 The 8 Pillars – #6, Evidence-Based Decisions

The 8 Pillars – #6, Evidence-Based Decisions

As an organization we have committed to only make decisions relating to our QMS following an analysis of relevant data and information.

So far, as we’ve discussed the principles we use to drive our business and establish our ISO standards, we’ve talked about: Customer Focus, Leadership Emphasis, Engagement of People, Process Approach and Improvement. But one of the other commitments we’ve made is Evidence-Based Decision Making.

All too often, companies rely on perceptions or “gut-feelings” to determine how successful a business is. “Why don’t we do this (or that) differently?” you may hear. “We’ve done it this way for a long time, and I think it would be better if we…” “I wish we could change the way we…” “It would be so much easier (or better) if we…”

But in the Testrods division of Regal Packaging Services, we’ve committed ourselves not to making any changes unless the data or the evidence indicates we need to change. So that means monitoring and testing everything we do.

Not too long ago, with the arrival of a new employee and a bit of fresh insight, we changed our inventory system from manual to automatic. We used to take time out to manually track our inventory so that we could apprise the production department about what test pieces to make next. That required hours of counting. It worked, and it worked well.

But after sitting down and discussing how we might recoup those hours of counting, it would be more efficient and effective if we allowed our sales software to track inventory for us. Up front, that required an investment of time, testing and proving. We didn’t make the change without knowing how long it took us to monitor inventory manually or how much the manual process affected the production line.

Previously, as we filled orders, we discovered that we were falling a little behind in our shipping timeline because we needed to refill several inventory bins with items that were sold out before we could ship an order. We knew that our track record was 24-48 hrs to ship standard/stock items, and even in getting custom orders out the door. Over time, we discovered we were not meeting that standard, and that was especially true as our volume of custom orders continues to increase. With the change to an automated inventory system, we’re back on track and we’re saving the hours of manual counting we used to do.

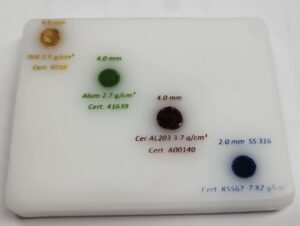

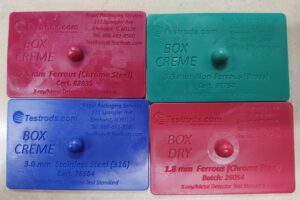

Another evidence-based decision was our commitment to only offering Stainless Steel 316 rather than other alloys, like 304. While many companies are using 304 for testing, the industry standard has always been 316. This is, in part, because 316 is harder to detect because it is less magnetic and less conductive than 304. In other words, if you’re testing using 304, you might miss any stainless steel 316 contaminant. But if you’re using 316, you are virtually assured to catch 304. We get asked by several customers every year to provide 304, but the evidence is clear, and in the interest of food safety and industry standards, we’ve held to 316 as our only stainless steel alloy.

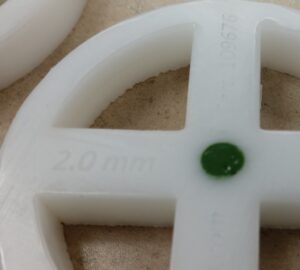

And, as a third example, quite some time ago we redesigned our test whip to include an engraved handle. The original version was identified with a simple label (showing metal type, size and certificate number) under a heat shrink covering meant to protect the label. After looking at several sample returns (or photos) from customers, we learned that the heat shrink did not provide a watertight seal. In a wet or frozen environment (or where condensation can occur), the label was degraded to the point where the test piece information was no longer legible. With the advancement of laser engraving, we moved to a test piece of the same length but with a three-inch handle. Now, the contaminant type, size and certification number is engraved on the handle, which will remain intact over the life of the test piece. Had we not paid attention to the issue, not only would we have lost sales, but we would be failing the customers’ interests as well as food safety standards as well.

We watch every part of our business, whether it’s recording non-conformance issues like a shipping error or delay, a production issue, a vendor problem or a marketing statistic. When the data shows there’s a change to be made, we adjust accordingly. We believe this kind of analysis puts us in a position to maintain the highest levels of product quality, customer service and cutting edge technology. Find out what makes us different when you order here on our website, or call us at 866-691-8560 or email testrods@testrods.com.