Metal Detector Certified Test Pieces Can Make A Real Difference

April 5, 2018Make Sure You Meet Metal Detection Test Standards

Metal detection test standards are very exacting, whether your machine is new or used, and it’s easy to understand why. The use of metal detectors is the only guaranteed way to ensure products are making it to the marketplace without metal.

While testing standards are important in any industry, nowhere are they more crucial than in the production of food products. Even the smallest slip up in this process can lead to serious injury. So it is vital to stay on top of your equipment’s condition at all times. That also means meeting the standards of the BRC (British Resource Consortium) and GFSI (Global Food Safety Initiative). The company’s well-defined HAACP plan is at play as well.

Testing

For this reason, it is generally recommended for any food grade metal detector to be tested hourly. In addition testing should occur at the beginning of each shift and at any product change. The more careful you are about testing, the less the likelihood of a problem. This can make a huge difference for your business. A great deal of product can pass down a production line in an hour. No company wants to lose product or place product on hold because a metal detector wasn’t checked. To adhere to these inline metal detection test standards, it is important that you use only top quality test pieces. You need test pieces designed to fit the exact specifications of your equipment.

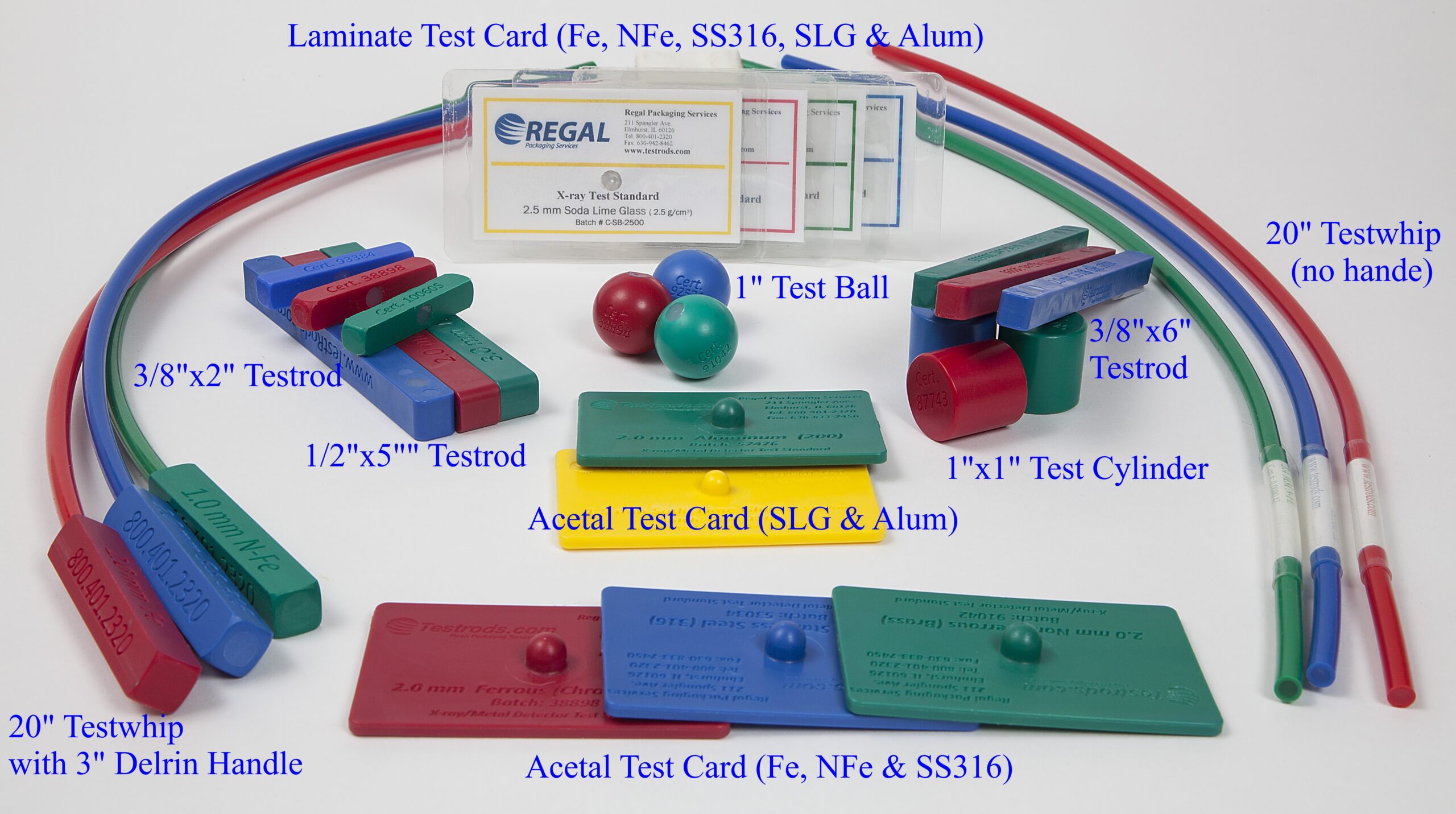

The testing process itself is really quite simple. Test pieces are manufactured in a variety of shapes. There are rods, spheres, cylinders and cards for a specific use, depending on the particular type of detector and product. Each test piece contains a small “seed” of metal varying in size from 0.5mm to as much as 12.0mm. Metals used are: ferrous, non-ferrous and stainless steel 316. The test piece is positioned either in or on top of a production style pack identical to the product being manufactured. The test pieces are then passed through the detector, ideally, 3x, with the test piece at the front, middle and trailing edge.

If the detector is working correctly, it should pick up the presence of the metal in the test piece and reject the pack. These metal detection test standards are the same for both new and used detectors and should work effectively every time.

Regal

Because Regal Packaging Services understands the need for top quality metal detector test pieces for every food grade metal detector, we offer three types: ferrous, non-ferrous and stainless steel 316. We also have aluminum, soda lime glass and ceramic for x-ray inspection. Our test pieces are available in a variety of shapes and sizes and can be custom built to fit your exact specifications. Simply let us know the kind of metal detection system you are using, and we’ll work with you to provide exactly what you need to meet your testing standards.

Those standards are important to us. That’s why we offer our customers a free Certificate of Conformity for each test piece you purchase. This way, you can be sure that your test pieces are up to food industry standards and will stay that way for the life of the piece. This way, whether you’re testing new or used metal detectors, you’ll have results you can count on.

Certifications

If you have purchased online from us, you can get a proper certificate depending on the type of metal or contaminant used. Just visit the “Certificates” section of our website. Once you’re confirmed as an authorized customer, you can get the certificate you need for your test pieces. You can also email us at testrods@testrods.com or call 866-691-8560. It’s that simple, and it can give you tremendous peace of mind. And more importantly, each certificate is good for a lifetime with no worries about expiration. As long as you’re using the test pieces, they’ll be certified. You can also call or email us for certificates.

Having a food grade metal detector that meets test standards for the industry is incredibly important, and that’s why you can’t afford to settle for less than the best. You want to be sure that your customers are getting the best quality product, and so do we. That’s why we’ve been putting such care and craftsmanship into our products since 1998.

We use materials that are virtually indestructible so that they’ll stand up to rigorous use, enabling you to keep your metal detection equipment working properly with regular testing. It’s that kind of attention to detail that sets us apart, and it’s why we’ve never had a dissatisfied customer in over two decades of doing business. That’s a standard that’s hard to duplicate and one that makes us very proud.

If you’re concerned about your system keeping your product and consumers safe, then don’t settle for second best. Come to Regal for your test pieces and rest easy knowing that your metal detector will be working at its best for years to come. That’s the gold standard in metal detector test pieces, and that’s what Regal Packaging is all about.

4 Comments

I’m trying to find out the required minimum for metal detecting test cards. We are a wholesale facility in California that packages an assortment of vegetables. We are currently using three sizes: 2.0 mm, 2.5 mm and 3.0 mm, however want to go a little higher : 3.0 mm, 3.5 mm, 4.0 mm. Could you help me find out how high I can go? Thank you

Ross,

That’s a great question.

I have sent you a direct email with a somewhat lengthy answer.

Feel free to email or post other questions.

It’s interesting to know about the importance of metal detection in the food processing industry. One of my cousins started working in canned food production two months ago. He said that their customers have complained about finding small pieces of metal in their products, so I think my cousin needs to read your information now.

Eli,

I get a “deer in the headlights” look when I explain what I do for a living and how it involves metal detection on food processing lines. I think we take food safety for granted until something goes wrong. I saw your comment as well on x-ray inspection systems. That kind of inspection can capture many different kinds of contaminants, including some plastics. Feel free to pass on our information. You may want to have them visit regalpack.com. Testrods.com is a division of Regal Packaging. We sell and service Fortress metal detectors (a worldwide brand) in Illinoi, Iowa, Indiana and Wisconsin. We also audit all brands of metal detectors and checkweighers. IF your relatives are outside our region, we can connect them to a local rep.