Make Sure You Meet Metal Detection Test Standards

April 5, 2018

Why Use a Metal Detector and Its Test Pieces In The Food Industry?

April 5, 2018Metal Detector Certified Test Pieces Can Make A Real Difference

In the world of metal detectors, standards are quite high and with good reason. Using certified test pieces on a regular basis can make a huge difference. That’s true for your business and for the protection and safety of consumers.

There is almost no avoiding contamination entirely, as all metal machinery and equipment is subject to natural wear and tear. But your should ensure that you have a good quality metal detection system in place. And you should be testing it on a regular basis. It’s a straightforward strategy to stay on top of this process and ensure your products are the best quality possible.

Not surprisingly, many industries, including pharmaceuticals and textiles, employ metal detection. But the food industry has the most vital need for promoting safety. That’s why quality metal detectors are key to meeting the increasing safety standards in the food industry. It’s also why it is so important to employ high quality, properly certified test pieces on a regular basis. Making sure that your products are safe is great for consumers. But it’s also good for your business, so there’s every reason to follow these safety guidelines.

Metal Detectors

There are several types of metal detectors currently in use today. But they are very different form the detector wands you might see in an airport or night club. While wands are common in personal security, detectors in the food industry must locate metal sometimes as small as 0.5mm. That’s a standard no airport detector will ever locate!

In general, the first line of defense in the food industry is an inline detector. This can be incorporated directly into the production line, usually at the very end, after the products have been packaged. This way each piece passes through the detector and is scanned for the presence of even the smallest possible particle. If a contaminant is detected, the product is automatically rejected so there is no danger of it reaching the public.

Certified Test Pieces

Once you consider the importance of metal detectors, it’s easy to see how test pieces are equally important. To be sure your metal detector is working properly, it’s necessary to use certified test pieces on a regular basis. These are small plastic devices that contain particles of ferrous, non-ferrous and stainless steel metals. The test pieces come in a variety of shapes and sizes. This helps make certain no matter what your metal detector or product, it meets the most stringent food industry standards.

Testing should be done on a regular basis according to a well-designed HACCP plan. This will most likely involve testing at the beginning of each shift and between each change of product. Each test should be carefully observed and documented so that any problems with contamination can be immediately and properly addressed.

The use of metal detector certified test pieces is really quite simple. The test pieces are put together into a sample pack that is identical to the product being manufactured. When testing is done, you should use ferrous, non-ferrous and stainless steel 316 test pieces to test. The packs should be passed through the detector 3x. Once at each position: leading, middle and trailing (last ) edge. If the detector is functioning properly, the metal in the test piece should be detected, and the pack automatically rejected.

Standards for Testing

This level of testing should meet the increasingly stringent food industry standards outlined by the BRC (British Resource Consortium) and the GFSI (Global Food Safety Initiative) as well as a company’s well-defined HAACP plan and ensure that your product is free from contaminants.

To accomplish this, it means using the best quality test pieces, designed specifically for your particular equipment and certified to meet industry standards. Since they are such an integral part of quality control for your business, you can’t afford to skimp where your metal detector test pieces are concerned. That’s why you need a name you can rely on to provide you with top of the line ferrous and non-ferrous pieces.

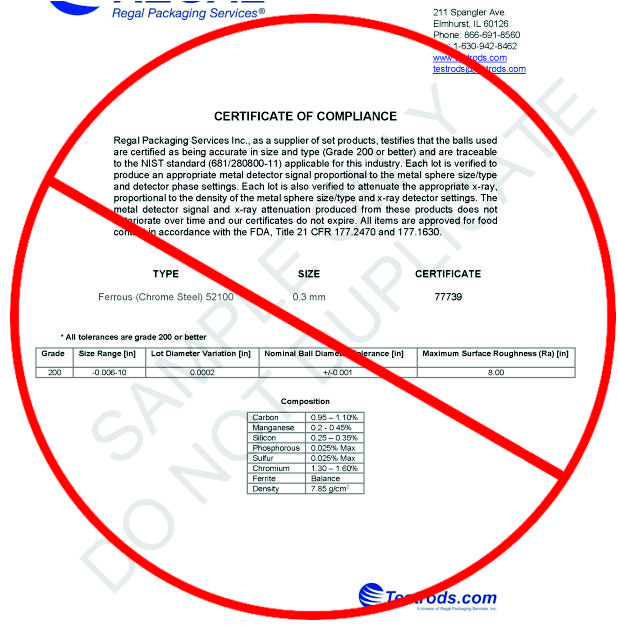

Since 1998, Regal Packaging Services has been that name for many in the textile, pharmaceutical and food industries. When it comes to metal detector certified test pieces, nobody measures up to Regal. We’ll custom design test pieces to fit your needs and provide free certification with each piece we produce so that you can breathe easier knowing your business is in good hands.

10 Comments

We want to buy standard test specimen for our metal detector in Fe, Non Fe and SS.

Abdul,

You’ve come to the right place. Do you know what size metals you need.

Are you just starting with a new metal detector or do you have standards that you are currently using?

If you are note sure, email us at testrods@testrods.com and we can provide you with an “Expect Sensitivity Table” that will give you a starting place.

We offer a full range of test pieces that will meet the needs of your application whether you’re using a conveyor, gravity fed or even a pipeline system.

Call us at 866-977-8663 or email testrods@testrods.com and we can talk through your application needs.

Is there a standard for placement of test wands when testing with product top of product, bottom of product or in product

Russell, the standard placement is actually determined by you and whatever you have determined are your standard operating procedures and written into your HACCP Plan. But there is definitely a best practice, and that is to place the test pieces as near the center of the aperture as possible, which often means placing it in the product. The middle of the aperture is the least sensitive place in the magnetic field of the detector. So if you can detect the metal (contaminant) there, you should be able to detect it anywhere else inn the aperture. Conversely, if you place the test piece near the wall of the aperture and use that for testing, you may be missing a contaminant anywhere closer to the center. Depending on your application, the center of the aperture may not be possible or practical, so you may want to choose a smaller size metal than what you would use in the center. For instance, if your standard for detection is 3.0mm Ferrous in the center, you may want to choose 2.5mm for testing closer to the wall because the detector is more sensitive there. I hope that helps. You can always email us directly at testrods@testrods.com or call me at 866-977-8663 or Justin at 866-691-8560. If needed, we can put you in touch with one of our techs who have a great deal more experience in the field and may understand the specifics of your application a little better. I will email you a copy of our “Expect Sensitivity Chart” which may be helpful as well.

Is there a standard for non-ferrous? Seems to me it could be made of Cu or AL or brass or bronze. These are all different. I know you should test for what is in your processing line but I ask – is there a standard metal that your non-ferrous should be composed of? Thx

Ray, sorry taking so long to respond. I’ve been out of the office for almost 2 weeks, so I appreciate your patience.

The standard in the food industry for non-ferrous is brass.

We also offer aluminum, but it typically is recommended only for x-ray applications.

Brass is actually an alloy of copper and zinc.

The brass we use has:

Copper -68.5-71.5%

Lead- 0.7% Max

Iron – 0.5% Max

Zinc – Balance

and has a density of 8.48 g/cm3

I hope that helps. Let us know if you have other questions.

Do the test pieces have an expiration date and do they all come with a certificate?

Ben, that’s a great question. We specify on our certificates that: “The metal detector signal and x-ray attenuation produced from these products does not deteriorate over time and our certificates do not expire.” As long as the contaminant is safely encased, there is no concern for a change in the effect the test piece will have on a metal detection or x-ray inspection system. There are companies that put expiry dates on their certificates as a means of getting to purchase new ones. All our test pieces come with free certificates and never expire. You just need to ask for them or download them from our website once you have an account here. We don’t send them out automatically with every order. We appreciate Marathon Cheese as a customer!

Thanks for previous answer.

Does anyone sell a test piece that is rod shaped not a sphere? We have been requested to use a 2mm by 0.5 mm test piece and its seems all are spherical in shape. This is due to a thin wire getting through a detector that was tested with a spherical test piece. Thanks

Ray, we don’t carry any test pieces with wire inside because we have never found a source. And finding a certified source would be even more difficult. The best we could offer is to have you send us wire samples that we could safely encase in a rod or card. The test pieces would be food safe, but the wire uncertified. Finding wire with a metal detector will always be subject to orientation.

See

https://www.testrods.com/orientation-and-metal-detection-are-key-to-success/

for more information.