The 8 Pillars – #4, Process Approach

December 1, 2025

The 8 Pillars – #6, Evidence

February 1, 2026 The 8 Pillars – #5, Improvement

The 8 Pillars – #5, Improvement

We have committed to achieving continual improvement across all aspects of our quality management system; it is one of our main annual objectives.

Having set our Customer Focus, Leadership Emphasis, Engagement of People, and Process Approach allows us to turn our attention to Improvement. But what does that look like? And how do you know you have really improved when you’re looking at your product from an inside view?

PROCESS IMPROVEMENT

It starts with a constant, consistent and almost ritualistic inspection of the daily orders that go out from our offices. We are not only checking to see if the right items are in the shipment, but that the items meet our aesthetic standards for readability and usefulness as well as checking for errors and defects. And if we have missed something, as a rare instance occurs, we are happy to replace it.

In the case of custom products, the sales team is always in conversation with production to determine the best means of manufacturing the needed test pieces. Just because a similar product was made for a previous order does not mean the next product will be made the same way. At the time of this article, we are collaborating with a customer to eliminate what is seen as a “void” under smart vision systems. It requires brainstorming and concerted effort to find new ways to make a product whose previous version could be improved, even if just a little bit.

NEW PRODUCT IMPROVEMENT

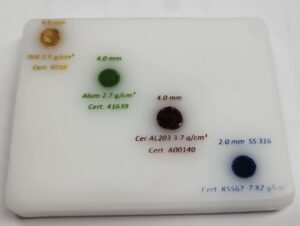

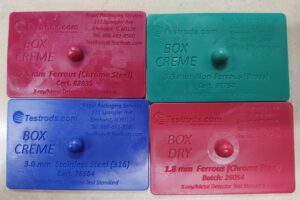

But suppose you have a product that looks good, is useful and goes out the door without mistakes and yet it does not meet the demands of your customers. This was the case with our laminate cards. Laminate is a very practical, useful product to a point. But laminate, even the rugged 10mil version we offer, will only tolerate a 4.0mm contaminant and is not as rugged, especially under wet or frozen applications, as other substances. So in 2014 we ventured out to design and manufacture an acetal (plastic) card, which is nearly indestructible under any conditions you will find in food manufacturing plants, and will contain up to 8.0mm contaminants. That was a significant improvement over the laminate card.

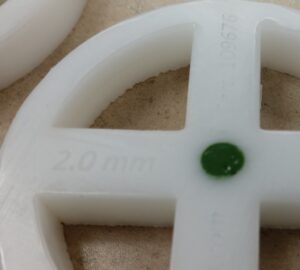

Then in 2016, in a continuing effort to improve the usefulness of test cards, we came out with our thermoform card, which is very much like a hard plastic, but has the capacity to form around literally a plethora of sizes and shapes of contaminants. In fact, in 2018, we upgraded our equipment so that we can now manufacture cards as large as 8×10” and hold up to 100 or more seeds. A variety of customers are using it to hold up to 20mm seeds. If you see us at the Food Safety Summit (booth 415 in 2025), we will have a sample thermoform card with a 4” ball just to show the versatility of this type test piece.

SAFETY IMPROVEMENT

But improvement is not always about new products. Early in the history of Regal Packaging Services, we used acrylic to manufacture our test pieces. But, as noted acrylicpedia.com, acrylic poses several concerns, including its tendency to shatter under pressure. And if a test piece shatters on a production line, it can mean wasted product, time and money. So we recognized the need for improvement and moved to acetal copolymer, which, as referenced by many suppliers, has “excellent dimensional stability.”1 And in the rare case where a brutal reject system manages to break an acetal test piece, it can usually be put back together in just a few pieces. Moreover, we have had customer send the broken test pieces back to us so we can testify first hand to the nearly indestructible nature of the plastic.

As the old saying goes, “there’s always a better way to skin a cat,” (no offense to cat lovers!) and we are looking for all the ways we can improve our processes, customer service and product quality. Call us at 866-691-8560 or email testrods@testrods.com and put us to the test.

1 https://dielectricmfg.com/resources/knowledge-base/acetal/