Orientation and Metal Detection are Key to Success

June 20, 2023

Understanding the 2 Most Common Ceramics: AL203 and ZrO2 is Critical for X-ray Inspection

August 1, 2023 Four Principles of Metal Detection:

Four Principles of Metal Detection:

(Based, in part, on “Metal Detection Guide” from Fortress Technology)

Contaminant Prevention

The first of the principles is based on the fact that you have metal detection system(s) in your production line does not mean there are no worries. Customer complaints are affected greatly by your effective controls (or lack thereof), poor working practices, and incorrect specifications (carried into the original design plans). These issues are more common than an actual metal detector failure.

Good manufacturing practices (GMP) focuses on minimizing any contamination because of:

- proper equipment selection,

- effective, regular testing,

- continued education and knowledge of industry standards,

- customer demands, and

- legislation that may affect production and processing.

Production Profit

Principle #2 is what everyone (in general) thinks about when it comes to business. But finding metal contaminant, especially if it is the end consumer finds it (and may have suffered injury), is a much more expensive proposition than the cost of implementing and sustaining an effective metal detection program. The proverbial “bottom line” can be greatly affected by metal found before shipping in the form of packaging waste, machinery damage, and loss of product.

Contaminated product, once it is shipped, can affect the consumer, create recalls, destroy your company or brand, lead to financial liabilities, and fester possible litigation. The benefits of a carefully crafted HACCP and a safe, well-implemented detection program will result in reduced failure costs, improve consumer satisfaction and brand loyalty, and safeguard your profit.

Customer Protection

The third principle declares that every food manufacturer or processor, from farm to fork, has a legal, moral, and ethical obligation to their customers, dictating they ensure the greatest level of protection in minimizing contamination of their product. The burden of responsibility lies with the food processing plant for the welfare of the customer as it applies to what comes out of your plant.

Given the increasing regulations and the rising knowledge of the consumer, manufacturers must continually look for the means to eradicate contamination of their products. Still, processes and procedures may not always mitigate against unforeseeable conditions, and failures can carry a personal cost as it relates to the food on every table.

Face it, when you lose concern for the end consumer, you are likely to end up in hot water, and the cost savings is never worth your failure at the dinner table.

Brand Promotion

As you look to brand your company and instill confidence in your product, branding does more than just maximize sales. Good branding engenders the consumers’ perception of a safe, quality product, and creates a loyal customer. Branding is a vital asset to be safeguarded.

Product contamination will bring financial consequences and sales decline. And, if the product recall is large enough, it can destroy your brand, or worse, your company. This means consistent quality and communication with your customer is fundamental to success. Rigorous compliance documentation gives you the means to demonstrate that success to your customer. If the level of loyalty is high enough, a product recall can even demonstrate your concern to the customer.

These four simple “P’s”, Prevention, Profit, Protection and Promotion, should stand as the basis for a successful approach to your HACCP and contamination procedures. You should never be operating on a reactionary basis on your food production lines. An aggressive program that gives you the chance to be proactive in your approach will help make these P’s not an afterthought but part of the intuitive thought process in the culture at your plants.

If you’re looking for to purchase a metal detector in Illinois, Wisconsin, Indiana or Iowa, contact us at:

- regalpack.com

- (630) 976-2390

- regalpack@regalpack.com

We also provide audit services on all metal detectors,

- detectoraudits.com

- (800) 976-2390

- inquiries@detectoraudits.com

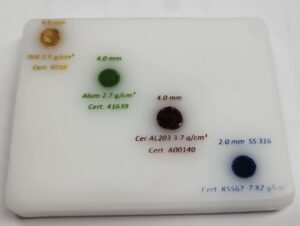

And you can purchase metal detection or x-ray inspection test pieces here at

- testrods.com

- (866) 691-8560

- testrods@testrods.com