Using Metal Detection Test Pieces in the Food Industry Helps Put Safety First

June 26, 2018

Metal Detecting Equipment: The Key to Safe Manufacturing

July 10, 2018Give Yourself Peace of Mind With Metal Detection Test Pieces

Using metal detection test pieces should be a regular practice for any business that employs metal processing equipment. No matter how careful you may be, it is nearly impossible to avoid contamination completely. Unfortunately, it is just a regular fact of life. The more a machine is used, the more it is likely to wear down. Then, as that happens small pieces of metal can flake off and end up in your product. That is a headache you do not need to have! And with the simple use of quality test pieces, you can easily avoid it.

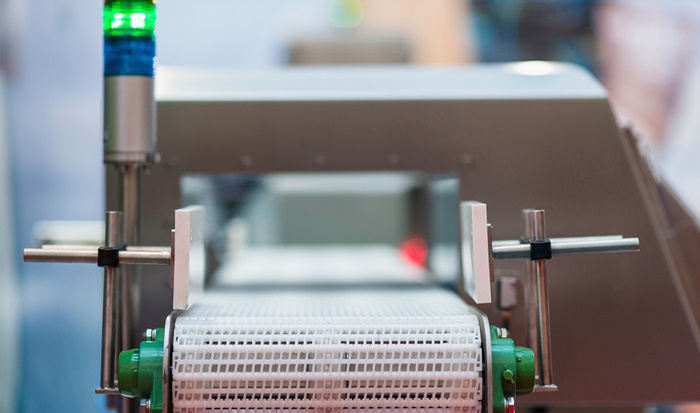

Metal detectors are used in many different industries, including pharmaceutical, textile and food. Each industry needs to ensure the quality of their finished products. Not surprisingly, one of the most prominent practitioners of conventional metal detection is the food industry. Here, safety is of the utmost importance. Because the use of metal detectors is so critical, the food industry employs very specific standards. To maintain those standards, manufacturers have to be sure that their detectors are working properly at all times. This is where test pieces come into the picture.

In most cases, food manufacturers use inline metal detectors that are incorporated directly into their production line. This way, each piece passes through the detector before final packaging so that they can be cleared off the line. If even the smallest metal particle is detected, the entire package is rejected before it can be shipped.

Testing

Even one contaminated package can end up costing millions of dollars, it is essential to use this detection process. It’s important that the metal detection test pieces are used to ensure that it works properly.

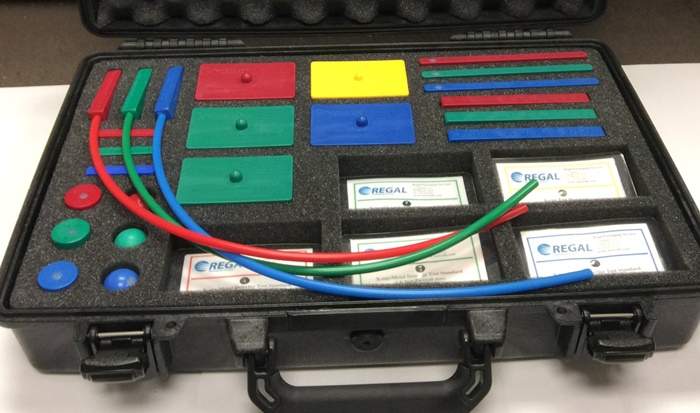

These test pieces are small plastic units that contain metal particles. They come in various shapes and sizes and can be customized to fit specific types of machinery. By running them through your metal detector regularly, you can help your business to meet exacting food industry standards. You can be sure that the products you provide to consumers are as safe as possible.

Because your entire business relies on this testing, it is imperative that it be done regularly. Machinery is in a constant state of degradation so contamination can literally happen at any moment. For this reason, the best practice is to test your detector on an hourly basis as well as at the beginning of each shift and any time you change products.

The testing process is straightforward. Metal detection test pieces are usually placed in a sample pack of the company’s product, which is then passed through the detector twice, once with the sample pack at the front end of the line and once with it at the end of the line. Provided the detector is working as it should, the test piece will be detected, and the offending pack rejected.

Industry Standards

To ensure that you are meeting food industry standards, you want to be sure that you are using the best quality test pieces, designed specifically to work with your equipment. Again, since even the smallest slip up in the quality control process can be very costly, you cannot afford to settle for second best when purchasing test pieces. You want to deal with a company that understands the exact nature of safety standards in the food industry and can provide what you need to keep your business running smoothly.

Regal Packaging Services has been doing just that since 1998. We provide metal detection test pieces that are made to measure and have been successfully used in the textile, pharmaceutical and especially the food industry. We will work with you to custom design test pieces to fit your specific machinery, and we will even provide certification with each piece, so you know you are getting the best. That way you can have peace of mind knowing that you are doing right by your customers by keeping your production process safe from start to finish.

2 Comments

Hi,

I have a question regarding testing samples. Do the testers have a specific expiration date or storage recommendations? If so, where can such information be found? I would appreciate your answer.

Kind regards,

Marcelina,

Our test pieces never expire. In fact, we indicate on our certificates that, “The metal detector signal and x-ray attenuation produced from these products does not deteriorate over time and our certificates do not expire.” As long as the contaminant remains safely encapsulated, there is no concern. As for storage, we recommend storing at a comfortable room temperature, however, there is no problem storing test pieces at a higher or lower temperature. The melting point is 164°C (327°F), the auto-ignition temp. is >400°C (752°F) and the decomposition temp. begins at 240°C (464°F). If you have an account on our website, you can find general cleaning instructions if you click the link at: https://www.testrods.com/download-your-test-piece-certificates/. You can always email us at testrods@testrods.com for more information.