Give Yourself Peace of Mind With Metal Detection Test Pieces

July 3, 2018

Every Food Grade Metal Detector Requires Regular Testing

July 27, 2018

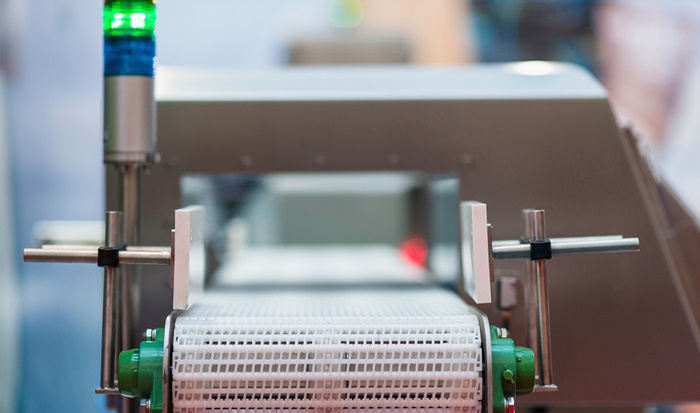

Metal detector conveyor - used to control quality in food or other products. Alarm is raised if system detects faulty or contaminated product.

Metal Detecting Equipment: The Key to Safe Manufacturing

Metal detecting equipment is an absolute necessity in today’s manufacturing process. If your equipment is brand new or if even it is used it will be subjected to regular wear and tear. This can lead to unintentional but costly contamination. Since there’s no way to avoid this , it is particularly important for manufacturers to use metal detectors to locate contaminants. Unfortunately, like any other machinery, metal detectors can also break down, and that is where test pieces can become crucial.

Since contamination is an issue, the general recommendation within the food industry is to employ a food grade metal detector. It should be tested it hourly, at the beginning of each shift and every time you change between products. When you consider how much a single contaminant can end up costing your business, it makes sense to be careful. Each step you take to ensure safety can keep you from facing severe consequences should a tainted product reach stores.

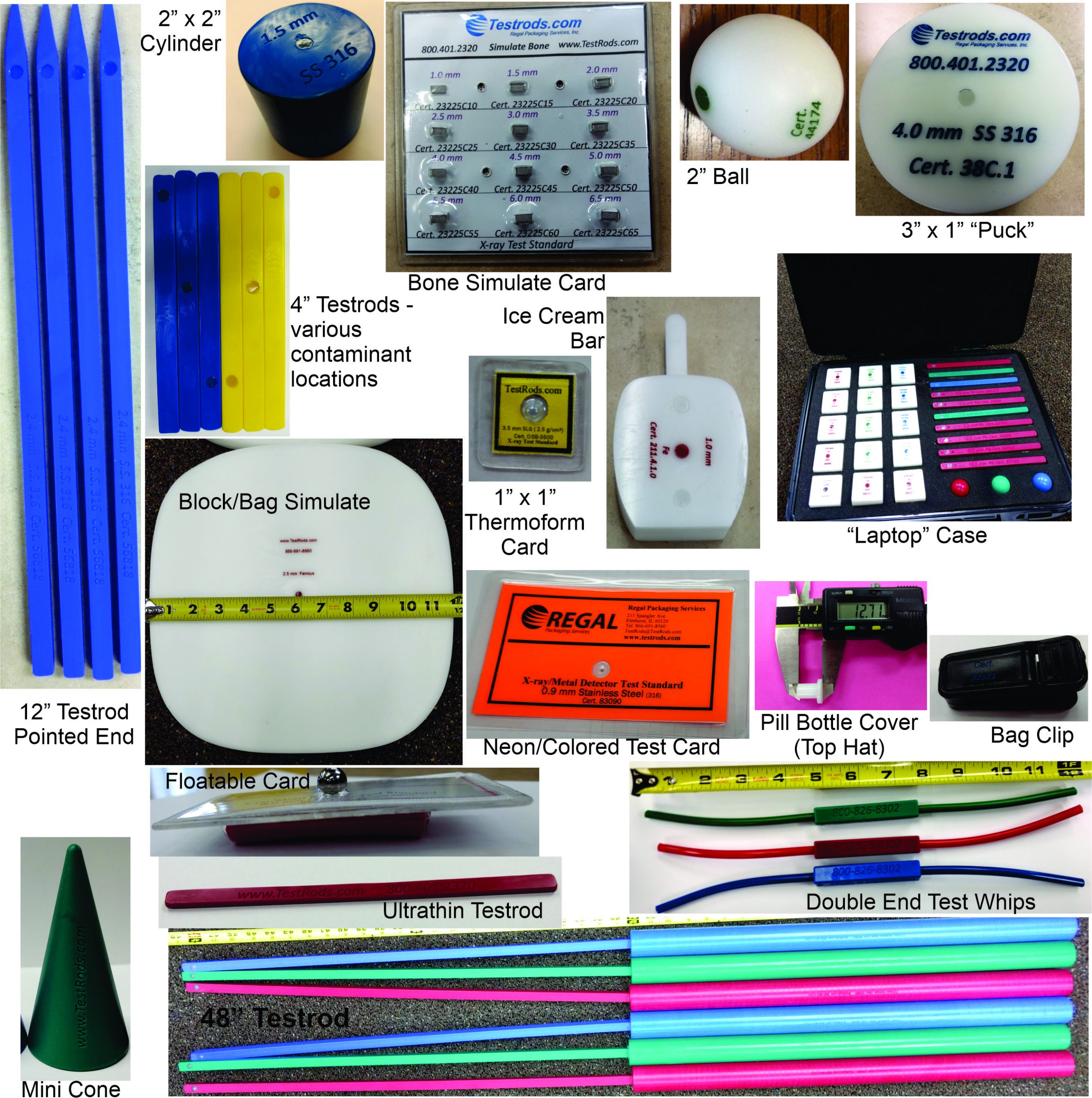

So how exactly do test pieces help to maintain the quality of your production process? It is no great mystery. The test pieces are made in a variety of types: wands, spheres, cylinders, etc. So they fit various types of metal detecting equipment. They are then made up of both ferrous and non-ferrous packs identical to the product being manufactured. These sample packs are then passed through the detector 3x, the leading, middle and trailing edge of the product. The detector is designed to pick up the presence of the metal and automatically reject the pack.

To accommodate every kind of metal detector, Regal Packaging offers four metals: ferrous, non-ferrous, stainless steel 316 and aluminum. We also produce soda lime glass, ceramic (ZrO2 and AL203), acetal, teflon and rubber for use in x-ray inspection.

Our quality test pieces can be customized to fit each customer’s individual specifications. We have worked with every type of metal detection system, so we can provide exactly what you need.

We understand how important it is for you to meet those standards with your metal detecting equipment. So we provide a Certificate of Conformity for each test piece we produce. You can be sure that you are getting top quality products that will give you accurate test results every time. To get the right certificate for your test pieces, just visit the “Certificates” section of our website. And since each certificate is good for a lifetime, you will not have to worry about it expiring. You can also email us at testrods@testrods.com or call 866-691-8560.

Your business relies on having satisfied customers, so you cannot afford to skimp when it comes to safety and testing standards. We understand that, which is why we have been providing quality testing pieces since 1998. Our pieces are made from materials designed to stand up to rigorous use so that you can keep your equipment running properly for years to come. Those results are just as important to us, and our own standards are reflected in our history of satisfied customers, a history that has lasted for over 20 years.

You need to be sure that your metal detecting equipment is functioning the way you need it to because your business is counting on it. Show your customers that you put their safety first by coming to Regal for the best test pieces available on the market. That way you will know that your business is in good hands and you can pass that confidence on to your customers.