Metal Detecting Equipment: The Key to Safe Manufacturing

July 10, 2018

Detecting Glass in X-Ray Systems

August 16, 2018Every Food Grade Metal Detector Requires Regular Testing

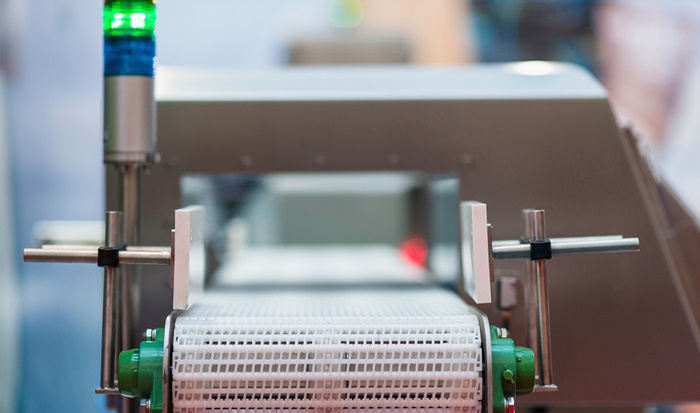

A food grade metal detector is a necessity for every manufacturing company. To understand why, all you have to do is check the headlines on any random day. You are likely to find at least one story about contaminated products being recalled. What most people do not realize is that those recalls can cost a company millions of dollars. The cost regarding customer confidence and satisfaction can be even greater. With that in mind, it is no surprise the food industry employs exacting test standards that include regular metal detection.

Of course, accurate metal detection is not possible if the detector itself is not running properly. That is why the food industry strongly recommends regular testing of all metal detection equipment. Each detector should be tested hourly or more. And testing should also happen at the beginning of each shift and every time you change between products. This way you can ensure that no contaminants are slipping through the cracks and working their way into your products.

Contamination

That kind of contamination is a more significant problem than you might think. No matter how well you maintain your processing plant, it is impossible to avoid wear and tear on your machinery. The more regularly a piece of equipment is used, the more likely it is to break down. You could be sending minute particles of metal into the products themselves. A food grade metal detector is your first line of defense against contamination. Yet even metal detectors can experience malfunctions, hence, the testing standards for this critical piece of equipment.

Test pieces formed into a variety of shapes and have small pieces of metal embedded into them. These are used to test your system. The pieces can be incorporated into sample packs that resemble the product being manufactured. Those packs are inserted into the group of products being scanned and run through the metal detector. This should be done at the lead, middle and trailing edge of the pack. If the detector is working properly, it will pick up the metal in the test piece and reject the pack.

Simple Operation

The smooth operation of food grade metal detectors is vital, and we provide the best quality test pieces on the market. They are available with metals (ferrous, non-ferrous, stainless steel 316 and aluminum) as well as soda-lime glass, and ceramic (ZrO2 and AL203), acetal , teflon and rubber. Our test pieces can be constructed to fit your specifications. They are available in a wide variety of shapes, sizes and colors, always with food industry testing standards in mind. And we can meet every custom challenge.

To that end, we also provide certification for every piece we manufacture. That certification ensures that your test pieces will maintain those standards for the duration of their life, which is something that other test piece manufacturers cannot guarantee. That is because we understand how important the safety of your equipment is to your business. As our customers, it is important to us too, and we will go out of our way to make sure that you are getting exactly what you need to help you keep up with industry standards.

Getting quality test pieces may not have entered your mind before, but it is what Regal has been about for over two decades now, and we have a long record of satisfied customers to prove it. When it comes to safety, you do not want to cut corners, even when it comes to the tiniest detail like metal detector test pieces.

Success vs Failure

Your food grade metal detector can be the difference between success and failure for your business, so you need to be sure that it is functioning properly. Our test pieces, made with virtually indestructible materials designed to endure regular use, will help you breathe easier knowing that your equipment is working and your products are as safe as possible.

If you are working in the food industry, you cannot afford to let safety slide for even a second. With top quality metal detector test pieces from Regal Packaging, Inc. you will be able to stay on top of those standards and continue to provide your customers with products they can rely on. Don’t settle for second best; your business cannot afford it. Keep your metal detectors in working order with regular testing and give your customers your best.