Every Food Grade Metal Detector Requires Regular Testing

July 27, 2018

Why Do I Need Certificates of Conformity

January 9, 2019Detecting Glass in X-Ray Systems

Detecting glass in x-ray systems may seem like a complex idea, but it really is quite a good practice. It can save a great deal of time and money as well as protect customer. And there really is no reason not to employ this tactic in the food packaging industry.

Maintaining high-quality standards is vital for any business, and especially so in the food industry. Using a proper inspection process to detect possible contaminants is the best way to protect the quality of your products. And the safety and satisfaction of your customers is paramount.

Is it Common?

Glass is used quite commonly in many industries, including food packaging, and for good reason. Since it is non-porous, it won’t affect the flavor of the food inside, and it has a near zero rate of chemical interaction. So there are no worries that it will react negatively with the contents. Glass is also the only type of packaging that rates the FDA’s highest safety ranking – generally recognized as safe (GRAS). When you compare this to the potential for chemical contamination in other packaging materials it’s easy to see the difference.

That doesn’t mean that glass is entirely free of risks. While plastic has some flexibility and will re-form under pressure, glass is much stiffer and is prone to shatter. In the manufacturing and packaging process, there can be quite a bit of stress on individual items. Subsequently, there is a relatively high risk of breakage, which can result in glass shards contaminating food products. For this reason, there is an urgent need for detecting glass contaminants before shipping. Detecting glass in x-ray systems is the best way to ensure the safety of your products before they reach consumers.

So how exactly is glass detected?

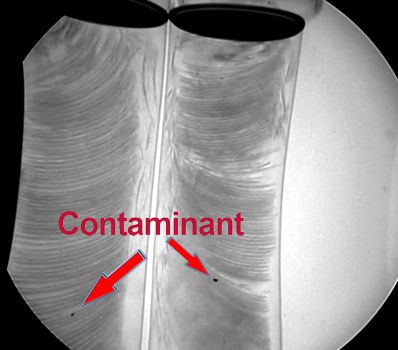

The x-ray process used to detect glass particles in packaging is very similar to x-rays used for medical purposes. It is not like airport security, where the process is designed to find much larger objects. Simply put, the x-ray beam is projected toward the object examined, and the object will cast varying shadows depending on the density of the material. Water and other products have a different density than glass, so the shadows cast by glass particles would be revealed.

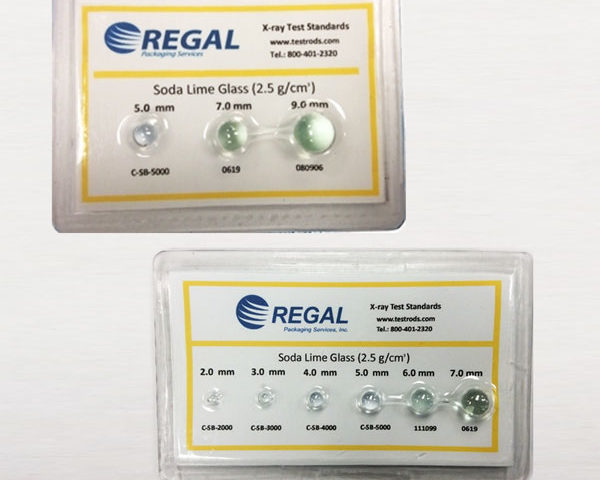

Density will also vary depending on the type of glass. In general, the glass produced today comes in five basic types. These include soda-lime, borosilicate, lead, aluminosilicate and fused silica. The glass most commonly used is soda-lime, making up 90% of all glass in regular use. Most food products have a density closer to that of water, which is much lighter than the density of glass. Thus the process of detecting glass in x-ray systems is usually quite effective. And Soda-Lime Glass it the only type offered on Testrods.com.

Foolproof?

As with any process, x-ray detection is not foolproof. In addition to different types of glass varying in density, the orientation of a glass particle within a product package can also affect detection. If, for instance, a glass shard is positioned perpendicular to the container, it may be difficult to detect as the density of the shard would be similar to that of the package itself. If that same shard were positioned parallel to the container, however, the thickness of the shard would be likely to stand out more, making it easier to detect, particularly when a multi-beam x-ray system is used.

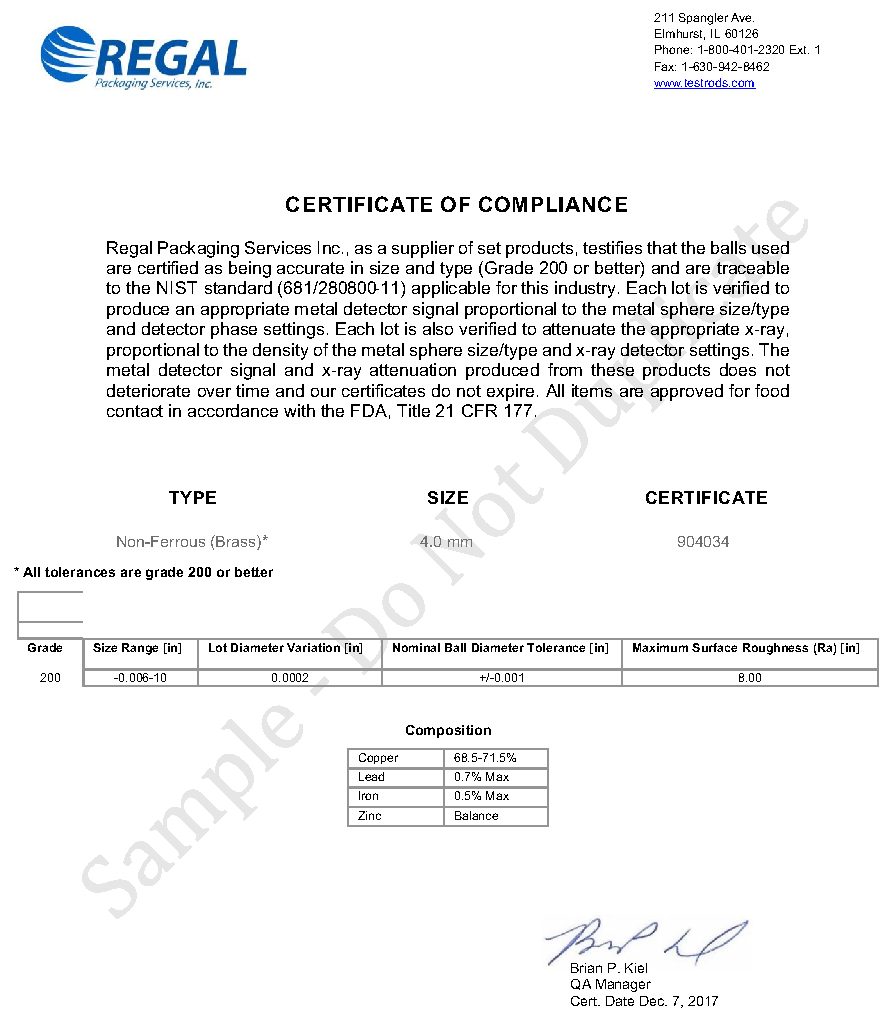

Whether you are detecting glass in x-rays systems with a single beam or multiple beams, it is crucial that you ensure the accuracy of your detection equipment and the best way to do that is by using custom-made test pieces designed specifically to allow for regular maintenance checks. These specially designed pieces, which range in shape and size, are included in sample product packages that are then passed through your detection system. If everything is functioning as it should, the test piece should be detected, and the pack automatically rejected.

For this process to work correctly, you need to use the best quality test pieces certified to meet industry standards. That’s where Regal Packaging Services comes in. They have been at the forefront of the industry since 1998, providing top of the line test pieces made of aluminum, soda-lime glass, and ceramic, specifically for use in x-ray systems. All of their test pieces, found at testrods.com, are custom designed to fit your needs, and each piece comes with certification to give you the added security you want for your business.