What to Look for in a Metal Detector Test

June 6, 2019

Best Practices For Metal Detection In The Food Industry

June 17, 2019

Using X-Ray Systems Test Pieces is different from metal detection because it is based on density

X-Ray Systems Test Pieces

Using X-Ray Systems Test Pieces can be a vital part of any company’s safety procedures, especially in the food industry. X-ray systems are much more expensive and require an understanding of a different technology. X-ray inspection is based on density and allows you to test for a broader range of potential contaminants. In turn, this offers a level of security beyond that of ordinary metal detectors.

Many companies employ a combination of both metal detectors and x-ray systems in order to cover all their bases. Even one instance of contamination can cost a considerable amount of time and money as well as damage to a company’s image. It makes a lot of sense to do everything possible to avoid it.

Metal detectors and x-ray systems are used in everything from pharmaceutical packaging to textile manufacturing. But perhaps the most important application of these critical safety procedures is in the food industry. Contamination of food products can be a major health concern. It should be avoided at all costs, which is why the USDA and FDA have enacted strict safety guidelines. And it’s the reason you need metal detection and X-ray systems test pieces

Ensuring Safety

In order to ensure safety, it is necessary for companies to regularly test their products. As always, this should happen at various points throughout the manufacturing and packaging process. This means having a series of metal detectors and/or x-ray systems positioned at various points along the production line. This provides certainty in detecting the presence of any contaminants before the product reaches consumers.

Unfortunately, with regular use, machinery can break down and when that happens, it can lead to dangerous results. X-ray systems test pieces and metal detection test pieces can be used to ensure that equipment is operating properly.

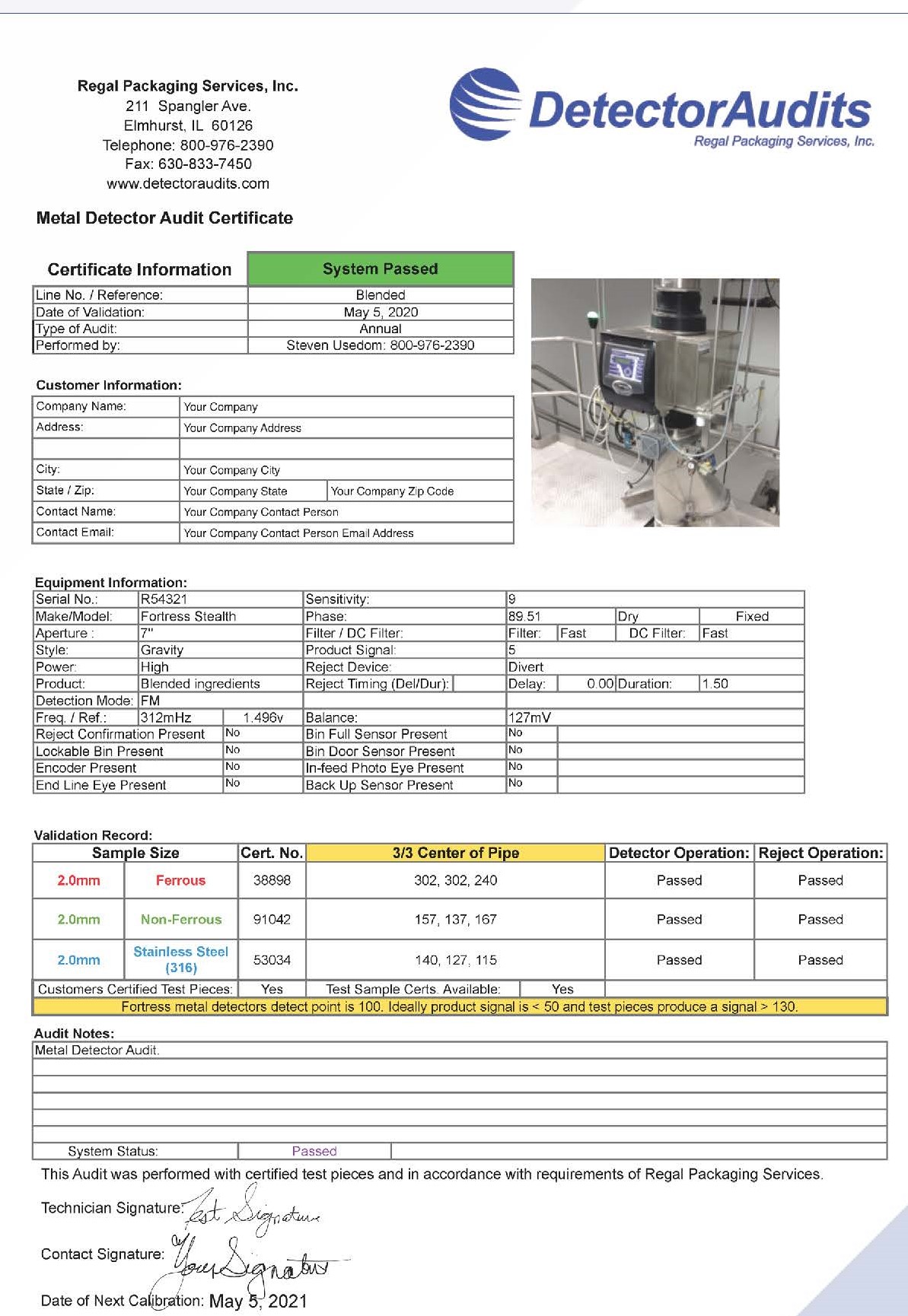

The process for testing equipment is pretty straightforward. A sample of the product is created and a test piece inserted into the sample. The test sample is then inserted into the production line and run through each machine.

If the machinery is working properly, it will detect the presence of the test piece and automatically reject it. For compliance with all safety standards, testing should be done (at minimum) at the beginning and end of daily production. Add to that every shift change and any time you change the production machinery settings or it’s down for repairs.

Accuracy

Because x-ray depends on density, this affects what type of contaminant standard is achievable. In order to ensure the accuracy of testing, X-Ray systems test pieces systems should include a variety of contaminants. This could be metals like aluminum, stainless steel 316, soda-lime glass, ceramic or rubber. Not all metals, such as copper or other contaminant possibilities, like stone, are available. That’s because they are not available in certifiable standards. Stone, for instance, can have a broad range of densities depending on its source and type. But by employing a wide variety of test materials, you can get a more accurate reading of your x-ray system capabilities. You will know, then, that it is operating properly to keep your products contaminant free.

Innovation – Research and Development

Bone, as well, can present a difficult challenge, because it depends on animal type, age, feed and calcification. Regal Packaging has found a way to simulate bone using a material that can be set to the desired density. Customers generally purchase a multi-card (with a variety of sizes) to determine what can be achieved. Then they will purchase an individual card for daily, regular testing.

Aside from testing frequently and using the widest range of quality test pieces, it is also important to position the test pieces properly. The goal is get the most accurate reading from your x-ray system. Also, you’ll want to run multiple test samples at the beginning, center and end of a batch. It’s the best way to determine that your x-ray system is working properly at every point along the process.

No matter how often you run tests and how accurately you position the test packs, your results can’t be guaranteed without the best quality X-ray systems test pieces. Nobody understands this better than Regal Packaging Services, Inc. We have the field experience to back up our innovations. And it’s the reason we offer a full line of test pieces in a range of shapes and sizes. Research and development give Regal the ability to meet the challenges of any product type or detection system.

Customer Focused

We work closely with each customer to provide them with the pieces they need. We fit their system and we certify each individual piece so you can be assured of their quality and durability.

Our pieces come in a variety of shapes, with standard metals ferrous, non-ferrous metals, and stainless steel 316. For x-ray systems, we also manufacture test pieces in aluminum, soda lime glass, ceramic (ZRO2 and AL203), acetal, teflon and rubber.

When it comes to your business, you can’t take safety lightly. That means keeping your x-ray system working at its best with high-quality test pieces from Regal Packaging Services.