Detecting Glass in X-Ray Systems

August 16, 2018

Commitment to Food Safety

January 10, 2019 Why Do I Need Certificates of Conformity

Why Do I Need Certificates of Conformity

What is a Certificate of Conformity?

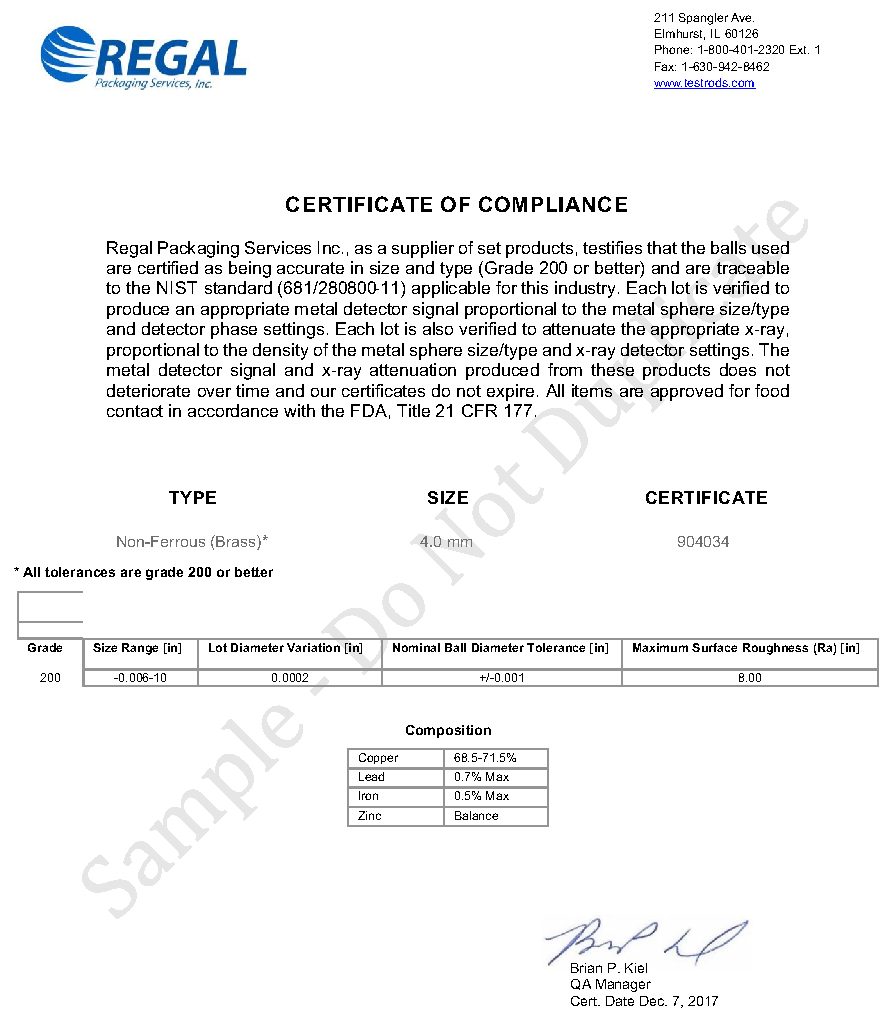

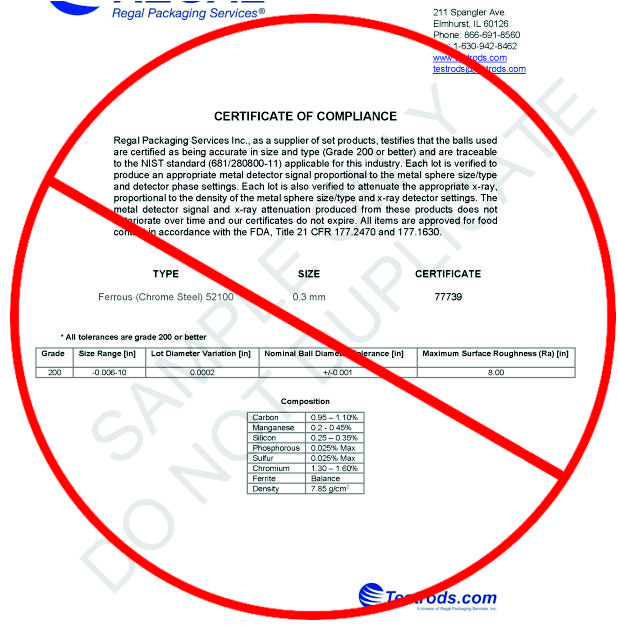

Certificates of Conformity are critical in the world of Quality Assurance. A COC is the document stating that the test piece supplied meets the required specifications for the industry. This is provided by a competent authority or vendor (like Regal Packaging Services). We offer our customers a free certificate with the purchase of every test piece. It is made available either as sent with an order, by download or by email. These certificates of conformity, through Regal’s Testrods.com division, never expire or need to be updated. They are good for the life of the test piece.

Why Do I Need a Certificate of Conformity?

Certificates of Conformity provide the means to track a test piece from your production line back to the company who provided it. And even back to the company who made the metal inside the test piece. However, the vendor who will supply the certificate is ordinarily the manufacturer of the test piece. This covers the metal as well as the plastic or other material housing the metal. Metal is sourced by a company, like us, and then used to insert into various type of test pieces. Regal Packaging certifies that the housing and adhesive are food grade safe and the metal meets NIST standards.

When an auditor arrives to inspect a production facility, he/she will most likely ask to see the certificates of conformity. He needs to know about the test pieces used for the test pieces being used on the line. There will always be a method, usually a numbering system, which identifies the corresponding certificate. An inspector may want to track the validity of conformance to a HACCP plan or industry standards. You have the assurance that can be accomplished. In other words, for example, if you say your metal detection system can detect 1.0mm Ferrous material, you can confirm that for the inspector. We can show that as the supplier for your test pieces, we have, in fact, provided you with the test piece to validate that claim.

Why Do Certificate Numbers Seem So Random?

Certificate numbers can vary widely because a batch or lot of metal. This is the number used identify a variety of variables, including date, time, machinery and metal origin. A certificate for a 2.0mm Ferrous test piece may have two, three, or any multiple of certificate numbers. This happens over time based on the variables described above.

Why Does the Same Certificate Number Appear on Different Kinds of Test Pieces?

Certificate numbers are always tied to the metal inside the test piece. A cylinder with a 2.0mm ferrous ball can be the same as a card, testrod or other type test piece. This is true as long as it houses metal from the same batch (lot).

Do I need to update my certificates annually?

Certificates of conformity should never need to be updated unless you have purchased new test pieces with a different number. The metal detector signal produced from these products does not deteriorate over time. So any company proposing that certificates must be updated is likely looking for a way to make an additional sale for something unnecessary.

How much can I expect to spend for certificates of conformity?

Depending on where you purchase your test pieces, you can expect to pay as much as $100 each for every certificate. At Regal Packaging Services, we provide all certificates at no charge. We believe the certificate is an extension of the product. We make certificates easily available via our website or by contacting customer service. Certificates of conformity can be mailed, included with your order, emailed or downloaded from our website.

What makes certification in the Food Industry any different from other industries?

In regard to test pieces, food safety certification should always be a third-party process. This is verification demonstrating that processes and systems meet accepted food safety standards. In the food industry, there is a unique distinction from other certificates such as supplier declarations, laboratory tests or other reports. Certification within this industry is based on test results, inspections and audits. These are ultimately designed to protect consumers, and to give the public confidence in food products and the industry. When metal shows up in food because a company failed to use certified test pieces, it affects the company’s credibility.

And it won’t matter whether the contaminant is discovered in a canned, bagged, boxed, frozen or fresh product. Consumers will begin to mistrust the food industry at a foundational level. Any given company can destroy its reputation when a contaminant is uncovered in its brand. So test pieces, whether in metal detection or x-ray processes, while a small part of production, are no less critical.

When no legal policies are in place for a particular sector of the food industry or a need to conform to standards, food safety certification at every level should be considered more imperative than simply voluntary. In such cases, a company may set its own levels of certification, such as a HACCP plan, conformity to another given standard, such as an in-house product constraint, or a blueprint for gaining a strategic advantage in the marketplace, always keeping in mind that food safety certification works as an incentive to consumers for company and brand loyalty.

Trustworthy Source

With increased awareness and news highlights from recent food recalls, consumers are insisting on an increase in standards in every part of the global supply chain. Those businesses that make proper use of certified test pieces purchased from a trustworthy enterprise will gain a competitive benefit in the market.

Due diligence is absolutely vital in testing. At a basic level, it demonstrates that management is meeting its legal responsibilities as it relates to food safety and regulations and is doing so efficiently and effectively. In a variety of circumstances, an operational HACCP plan can serve as a defense in against litigation of food contamination. Many associations such as packing, horticultural, packaging and quality assurance offer safety standards and certification procedures that may comply with or identify national standards and may be harmonized with the international conventions of the HACCP plan.

The fact that the Testrods division of Regal Packaging Services is certified to ISO 9001:2015 standards gives you the confidence that our systems and manufacturing policies are monitored, consistent and designed specifically to the needs of the food, pharmaceutical and textile industries. Our sales and service teams have thousands of hours experience in the field, assisting our customers meet the demands not only of their own HACCP plan but also of the BRC and GFSI. We recently began cataloging and maintaining records of NIST documentation and sphericity reports. You won’t find that kind of process among any of our competitors. We know the ever increasing demands of the marketplace and understand the value of being a dependable, knowledgeable and qualified vendor for metal detection and x-ray inspection verification test pieces. And our direct support and participation in the field by way of Fortress Technology metal detector sales and audits on all brands of metal detector and x-ray systems demonstrates we’re a cut above the competition.